We are open to new technologies and value principles such as professionalism, loyalty, and trust. We continuously upgrade and invest in our machinery while focusing on the ongoing development of our employees. As a result, today we are proud to have a stable team of qualified specialists, modern equipment, and the trust of our clients.

The best materials

We process thermoplastics. For production, we use both new, virgin materials that are certified and approved for processing within the EU, as well as eco-friendly recycled materials. Our investment in new machinery, improved mechanical and hydraulic systems, which shorten production cycles and offer better control of the entire process, makes production energy-efficient and environmentally friendly.

A company with a high technological level

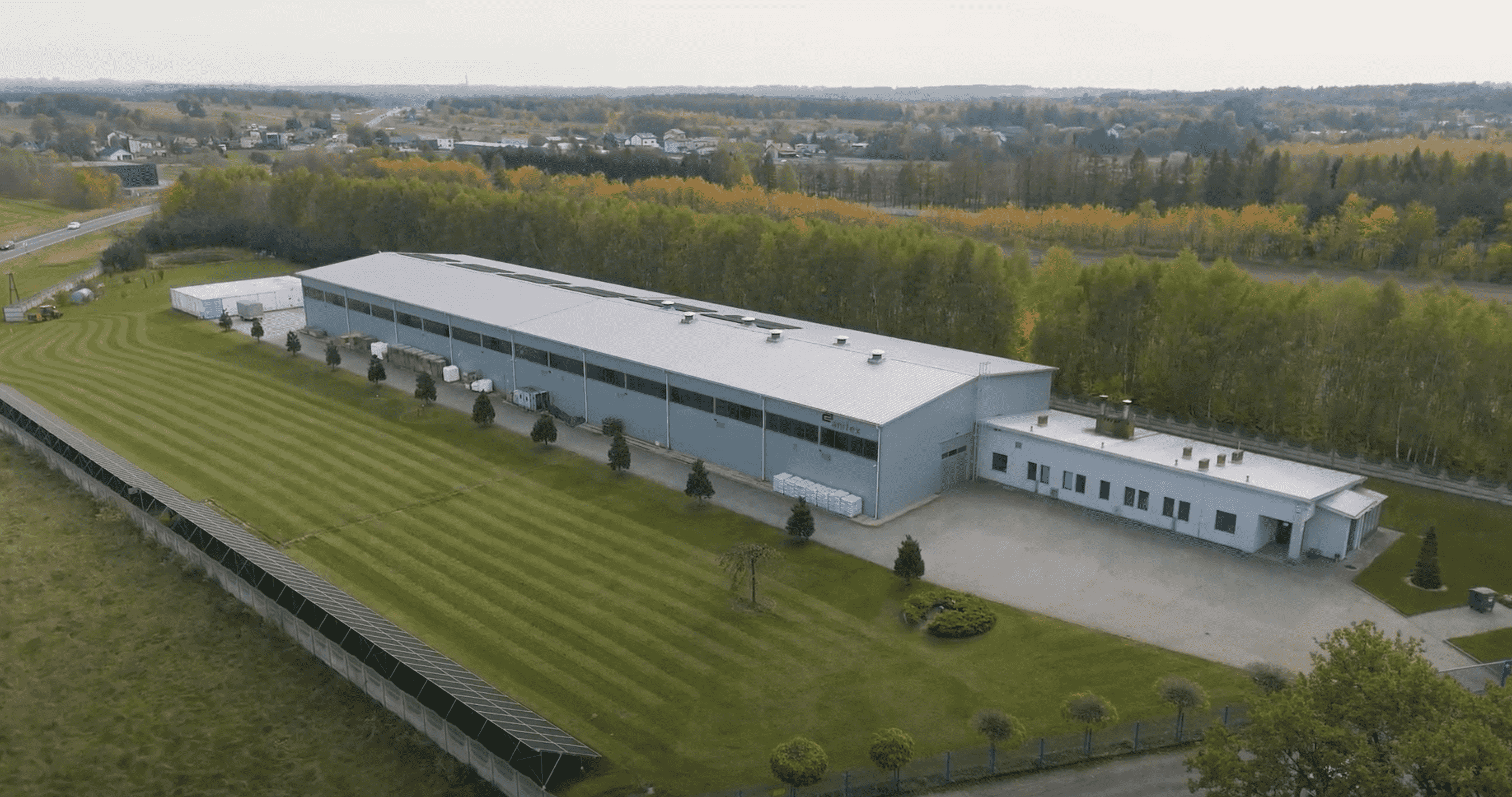

The production hall in Lgota is a modern machine park with a wide range of capabilities. Equipment with clamping forces from 22 to 600 tons allows us to fulfill any order within this range. It is possible to produce parts using standard injection moulding, two-component injection moulding, and gas-assisted injection moulding.

The equipment in our machine park ensures process repeatability. Why is this so important? Because it guarantees that every batch of products has identical parameters: material composition, colour, and structure.

A good employer

Anitex currently employs around 50 people. Each of them can count on a full benefits package, insurance, safe working conditions, and opportunities for growth.

“We believe in making work easier by raising qualifications. Our company is moving towards new technologies and greater automation of production processes, which requires our specialists to acquire new knowledge and skills. We strive to provide this knowledge by organising or sending employees to the best workshops and training courses. We invest in people because it is just as important as investing in better machines — as a result, some employees have been with us for over 20 years!” said Anita Korzekwa.

High standards, care, safety, and development opportunities led us to become the winner of the 2011 competition organised by the National Labour Inspectorate “Employer — Safe Work Organizer”. We took first place in the small business category in the Silesian Voivodeship.

Free quotation ready in one day

Company history

We officially started our business on April 15, 1983. However, the history of our company began a little earlier, when we purchased our first two injection moulding machines.

This marked the beginning of toy production and the provision of injection moulding services. As a team of mechanics by education and passion, we grew in the industry, driven from the very start by curiosity, energy, and passion.

Year 1985

The year 1985 turned out to be the first breakthrough year in our company's history. It was then that we moved our headquarters to Gminna Street in Częstochowa. To this day, our offices, store, design studio, toolroom, and assembly workshop are still located there.

The 1990s

At the beginning of the 1990s, we decided to change our business profile: while continuing to focus on the dynamically growing plastic processing industry, we discontinued toy production in favour of manufacturing parts for strollers.

Year 2006

In 2006, we started a project to build a new Anitex branch in Lgota, located a few kilometers away. In May 2010, we moved our machine park there. In 2014, we began further work to expand the production hall at this location.

Today

Today, Anitex offers its clients parts and complete assemblies for the construction of photovoltaic systems, recuperation, air conditioning, mining systems, as well as comprehensive injection moulding services — from idea or design through tool manufacturing to the final product. We strive for even greater automation and the implementation of eco-friendly processes.