"Plastic injection moulding is one of the most efficient

and widely used production methods for both simple

and complex plastic parts."

• Mechanical engineering

• Mining industry

• Electronic controller housings (air conditioning, ventilation, heat pumps, central heating)

• Solutions for animal production

• Household appliances and consumer electronics

• Research and development

• Pharmaceutical products

• Food products

• Parts for car seats

• Moulds for toy manufacturers

Check a few steps to bring your product to market

Mass, serial, and prototype production — we can manufacture any plastic component. Even the simplest moulds require the right machines and know-how.

- I don't have a ready-made mould

- I have a ready-made mould

- Energy

- Consumption

- Industry

- Technology

Do you have any questions?

Check our FAQ or talk to our expert.

Let’s talk about your project

Our specialists will answer all your questions, advise on the best technological solutions, and prepare the most favorable offer tailored to your needs.

1 | What is the mould manufacturing time?

This depends entirely on the complexity of the mould design and can range from 2 to 8 months. The final delivery time also depends on the current production queue.

2 | What is the lead time for orders with a ready-made mould?

The lead time largely depends on material availability, production volume, and whether post-processing is required. The final schedule is agreed directly with the client based on the order details.

Free quotation ready in one day

What does it look like in practice?

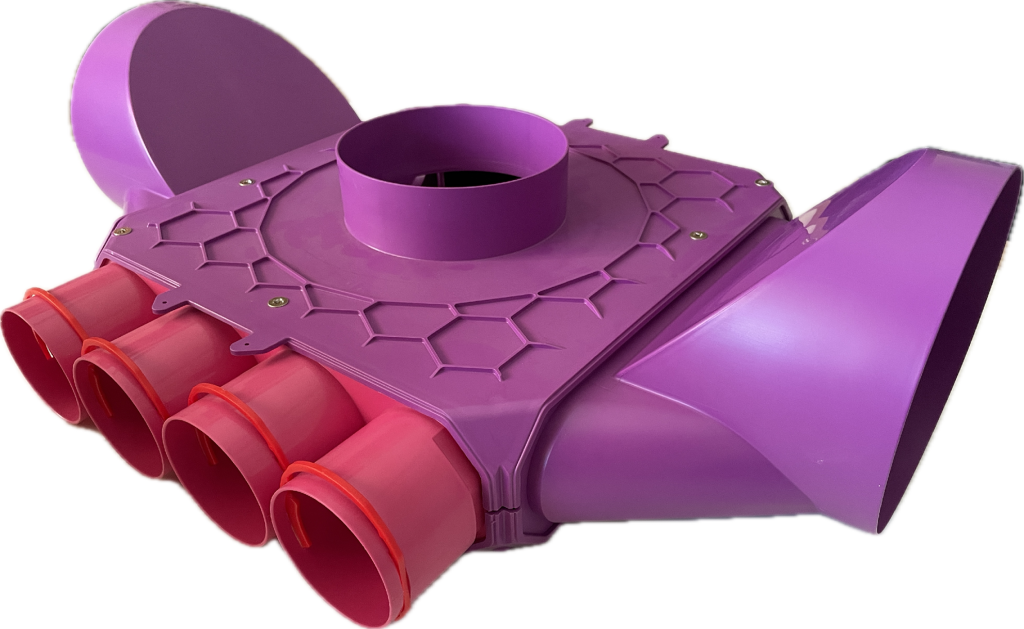

See what we have produced for our clients.

Conventional injection moulding

The conventional plastic injection moulding process is one of the most commonly used methods for producing plastic components. This process involves injecting molten plastic into a mould under high pressure. The first stage is heating the plastic until it becomes liquid, followed by injecting it into a closed mould that gives it the desired shape. Once the material has solidified within the mould, the finished part is removed. Injection moulding enables the production of complex shapes with high precision and allows for the rapid manufacture of large production series. Its advantages include high repeatability, efficiency, and the ability to use a wide range of materials.

Two-component injection moulding

Two-component injection moulding is an advanced injection method that involves simultaneously injecting two different materials into the same mould. This process makes it possible to produce parts with complex structures, where one material can serve a structural function and the other an aesthetic or functional role. The first component is injected into the mould, followed by the second material, which forms another layer on the already solidified first component. Thanks to this technology, products with various properties can be manufactured, such as different colours, hardness levels, or abrasion resistance. It is widely used in industries such as automotive, medical, and electronics. Two-component injection moulding also helps optimise production processes and reduce the number of assembly stages.

Gas-assisted injection moulding

Gas-assisted injection moulding is a technique in which plastic is injected into a mould while gas (usually nitrogen or air) is introduced into the part under high pressure. The gas forms an internal cavity or space in the product, allowing the creation of components that appear solid and thick on the outside but are hollow inside, significantly reducing their weight. This method helps save material and improve the mechanical and thermal properties of products. Gas-assisted injection moulding is used to produce various components, including complex shapes that need to be lightweight yet resistant to damage. This technology also shortens production cycle times and reduces manufacturing costs.